// Introduction //

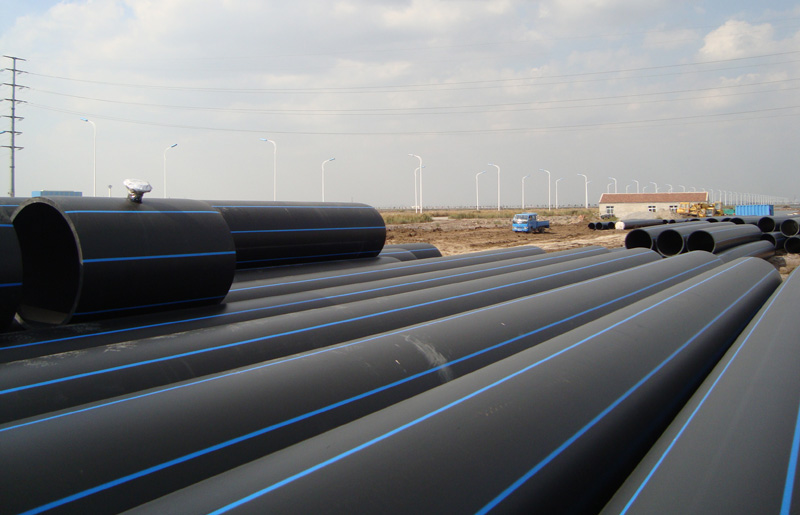

Polyethylene (PE) pipes shall be manufactured from polyethylene containing only those antioxidants, UV stabilizers and pigments necessary for the manufacture of pipes. PE Pipe is intended to be used for water supply intended for human consumption, including the conveyance of raw water prior to treatment and that of water for general purposes. Our company manufactured water supply PE pipe materials are PE100 resins.

Baosu have advanced Germany Battenfeld PE pipe extruders and fittings injected machines. We can manufacture a complete series pipe and fittings according to GB/T 13663-2000,GB/T 13663.2-2005,ISO 4427:2007 standards. We have 75,000 tons/year production capacity.

// Specifications //

ISO4427-2007 specifies water supply PE pipe used PE32、PE40、PE63、PE80、PE100 materials. GB/T13663-2000 specifies water supply PE pipe used PE63、PE80、PE100 three materials. These two standards’ SDR value, nominal pressure and materials are compared in Table 3.4.3.

Table 3.4.3 PE Pipe SDR Series, materials and nominal pressure compared in two standards Unit: MPa

|

SDR Series |

Materials |

|||||

|

PE63 |

PE80 |

PE100 |

||||

|

ISO4427 |

GB/T13663 |

ISO4427 |

GB/T13663 |

ISO4427 |

GB/T13663 |

|

|

SDR33 |

0.32 |

0.32 |

-- |

0.4 |

-- |

-- |

|

SDR26 |

0.4 |

0.4 |

-- |

-- |

-- |

0.6 |

|

SDR21 |

-- |

-- |

0.6 |

0.6 |

-- |

0.8 |

|

SDR17.6 |

0.6 |

0.6 |

-- |

-- |

-- |

-- |

|

SDR17 |

0.63 |

|

0.8 |

0.8 |

1.0 |

1.0 |

|

SDR13.6 |

0.8 |

0.8 |

1.0 |

1.0 |

12.5 |

1.25 |

|

SDR11 |

1.0 |

1.0 |

1.25 |

1.25 |

16 |

1.6 |

|

SDR9 |

12.5 |

-- |

1.6 |

-- |

-- |

-- |

|

SDR7.4 |

16 |

-- |

-- |

-- |

-- |

-- |

There are the same dimensions in GB/T13663-2000 standard and ISO 4427-2007 standard, e.g.table3.4.4.

Table 3.4.4 PE100 pipe nominal pressure and specification

|

Nominal outside diameter |

Nominal thickness |

||||

|

SDR |

|||||

|

SDR26 |

SDR21 |

SDR17 |

SDR13.6 |

SDR11 |

|

|

Nominal pressure |

|||||

|

0.6 |

0.8 |

1.0 |

1.25 |

1.6 |

|

|

32 |

-- |

-- |

-- |

-- |

3.0 |

|

40 |

-- |

-- |

-- |

-- |

3.7 |

|

50 |

-- |

-- |

-- |

-- |

4.6 |

|

63 |

-- |

-- |

-- |

4.7 |

5.8 |

|

75 |

-- |

-- |

4.5 |

5.6 |

6.8 |

|

90 |

-- |

4.3 |

5.4 |

6.7 |

8.2 |

|

110 |

4.2 |

5.3 |

6.6 |

8.1 |

10.0 |

|

125 |

4.8 |

6.0 |

7.4 |

9.2 |

11.4 |

|

140 |

5.4 |

6.7 |

8.3 |

10.3 |

12.7 |

|

160 |

6.2 |

7.7 |

9.5 |

11.8 |

14.6 |

|

180 |

6.9 |

8.6 |

10.7 |

13.3 |

16.4 |

|

200 |

7.7 |

9.6 |

11.9 |

14.7 |

18.2 |

|

225 |

8.6 |

10.8 |

13.4 |

16.6 |

20.5 |

|

250 |

9.6 |

11.9 |

14.8 |

18.4 |

22.7 |

|

280 |

10.7 |

13.4 |

16.6 |

20.6 |

25.4 |

|

315 |

12.1 |

15.0 |

18.7 |

23.2 |

28.6 |

|

355 |

13.6 |

16.9 |

21.1 |

26.1 |

32.2 |

|

400 |

15.3 |

19.1 |

23.7 |

29.4 |

36.3 |

|

450 |

17.2 |

21.5 |

26.7 |

33.1 |

40.9 |

|

500 |

19.1 |

23.9 |

29.7 |

36.8 |

45.4 |

|

560 |

21.4 |

26.7 |

33.2 |

41.2 |

50.8 |

|

630 |

24.1 |

30.0 |

37.4 |

46.3 |

57.2 |

|

710 |

27.2 |

33.9 |

42.1 |

52.2 |

64.5 |

|

800 |

30.6 |

38.1 |

47.4 |

58.8 |

72.6 |

|

900 |

34.4 |

42.9 |

53.3 |

62.2 |

81.7 |

|

1000 |

38.2 |

47.7 |

59.3 |

72.5 |

90.2 |

|

1200 |

46.9 |

57.2 |

67.9 |

88.2 |

|

// Characteristics //

1.Excellent toughness

PE pipe is a high toughness pipe, and its elongation at break exceeds 500%. PE pipe suits non-uniformity soil settlement and malposition, resistant earthquake good. It is demonstrated PE pipe which is the best choice of resistant earthquake pipe in the world.

In addition, PE pipe may coil, special small diameter PE pipe, reduces many fittings. PE pipe may bend and reduce construction difficulty.

2.Safety and health

Polyethylene consists of carbon molecule and hydrogen molecule, harmless, health and reliable.

3.Excellent resistant stress crack

PE pipe has low notch sensitivity, high resistant shear strength and excellent resistant scratch, resistant RCP and SCG. It is proved PE100 excellent resistant scratch ability.

4.Low temperature resistant impact good

PE pipe is brittle in very low temperature, can operate safety in -60℃.

5.Excellent abrasion resistant

PE pipe and steel pipe abrasion resistant experiment compared results show, PE pipe abrasion resistant is steel pipe four times.

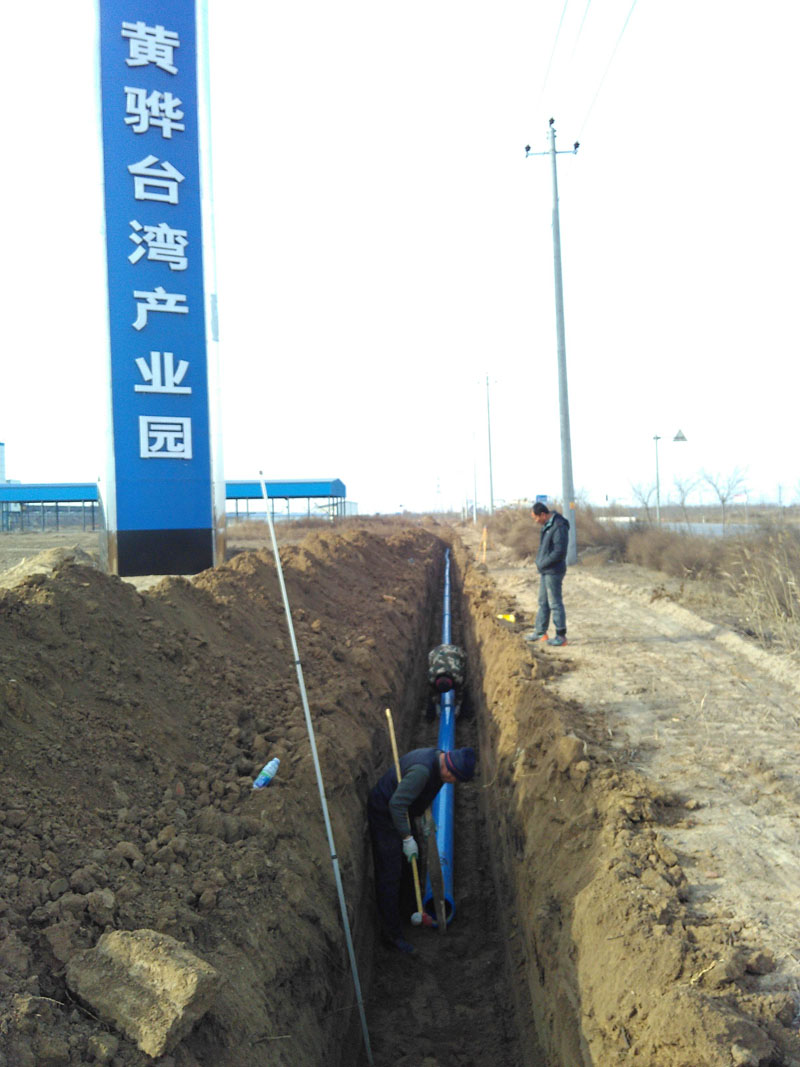

6.Special construction methods

PE pipe may be used in a few special construction methods, for example trenchless, crossed river, save capital, install faster.

// Performance and parameters //

PE100 pipe performance and parameters

| No. |

Items |

GB/T13663-2000, PE100 pipe |

ISO4427-2:2007, PE100 pipe |

Construction & Investment Baosu PE100 pipe type value |

|

01 |

Hydrostatic strength at 20℃ |

Hoop stress 12.4MPa,100h,No failure of any test piece during test period |

Hoop stress 12.4MPa,100h,No failure of any test piece during test period |

Hoop stress 12.4MPa,150h,No failure of any test piece during test period |

|

02 |

Hydrostatic strength at 80℃ |

Hoop stress 5.5MPa,165h,No failure of any test piece during test period |

Hoop stress 5.4MPa,165h,No failure of any test piece during test period |

Hoop stress 5.5MPa,165h,No failure of any test piece during test period |

|

03 |

Hydrostatic strength at 80℃ |

Hoop stress 5.0MPa,1000h,No failure of any test piece during test period |

Hoop stress 5.0MPa,1000h,No failure of any test piece during test period |

Hoop stress 5.0MPa,1000h,No failure of any test piece during test period |

|

04 |

Elongation at break, % |

≥350 |

≥350 |

≥400 |

|

05 |

Longitudinal reversion(110℃),% |

≤3 |

≤3 |

≤3 |

|

06 |

Oxidation induction time at 200℃, min |

≥20 |

≥20 |

≥30 |

|

07 |

Modulus of elasticity, MPa |

|

|

≥1000 |

|

08 |

Yield strength, MPa |

|

|

≥22 |

|

09 |

Poisson‘s ratio |

|

|

0.4 |

|

10 |

Roughness coefficient |

|

|

0.008 |

|

11 |

Linear expansion coefficient |

|

|

0.15-0.20mm/m.℃ |

|

12 |

SCG, en>5mm, 80℃, 0.92MPa |

|

|

≥500h, no failure of any test piece during test period |

// Application fields //

PE pipes are used in water transporting and distribution piping system no more than 40℃, including gas transporting and distribution, water supply, agriculture and irrigation, post and telecommunications, mine, municipal sewage and industrial applications.

// Installing //

PE pipe joining methods

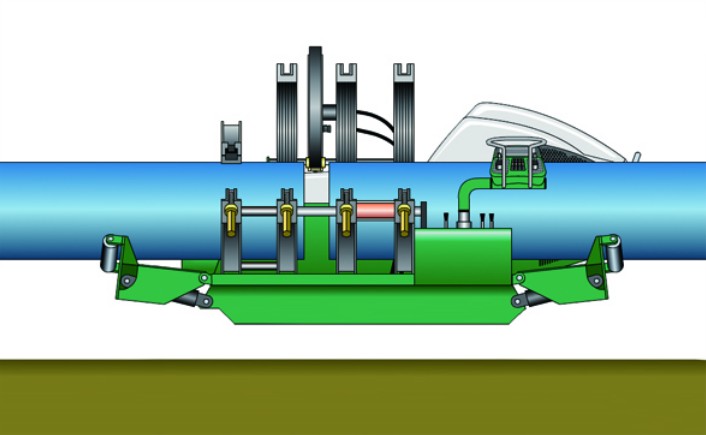

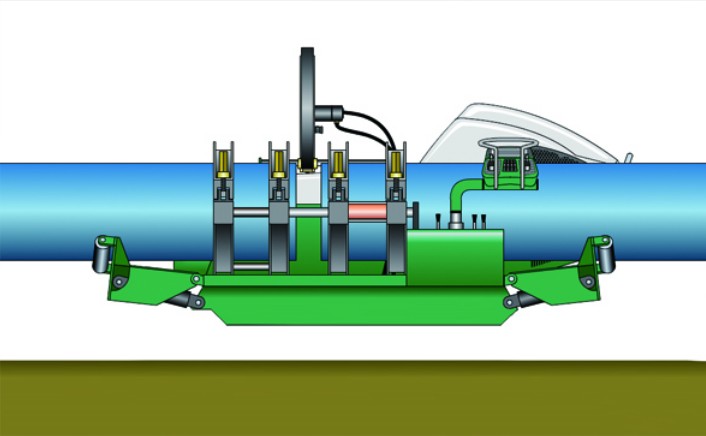

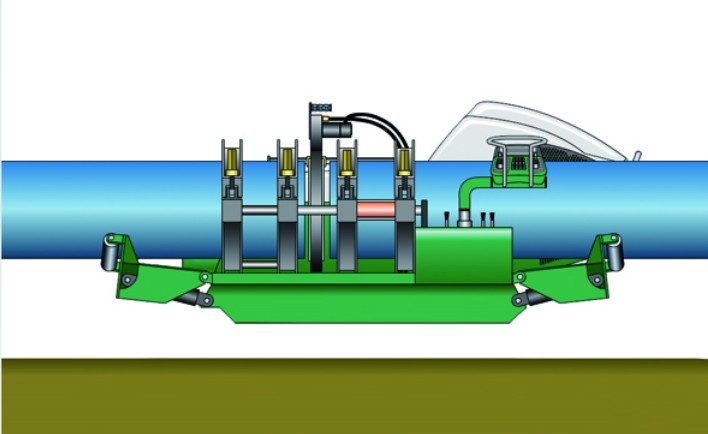

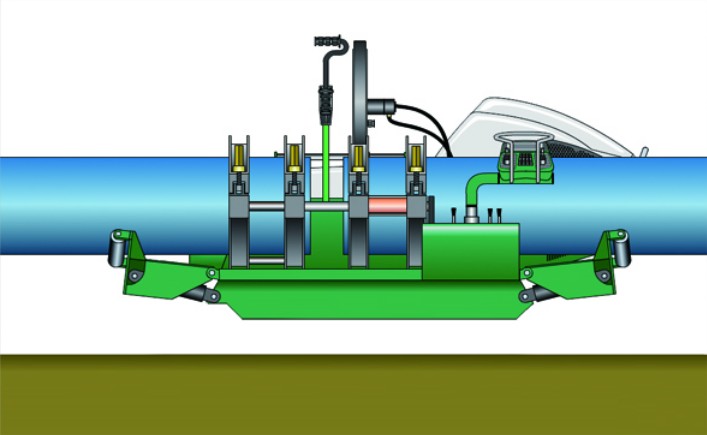

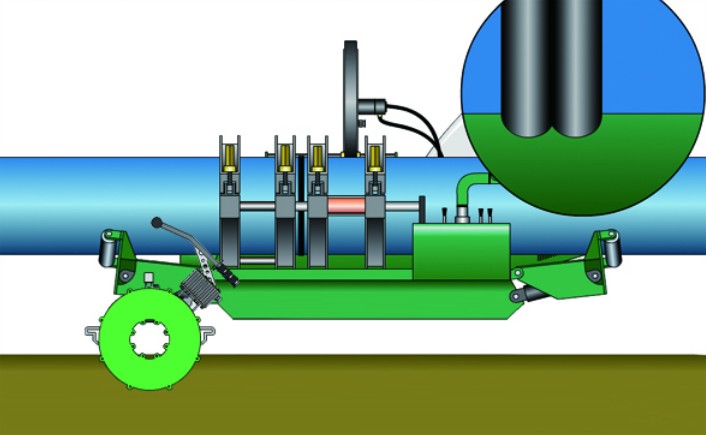

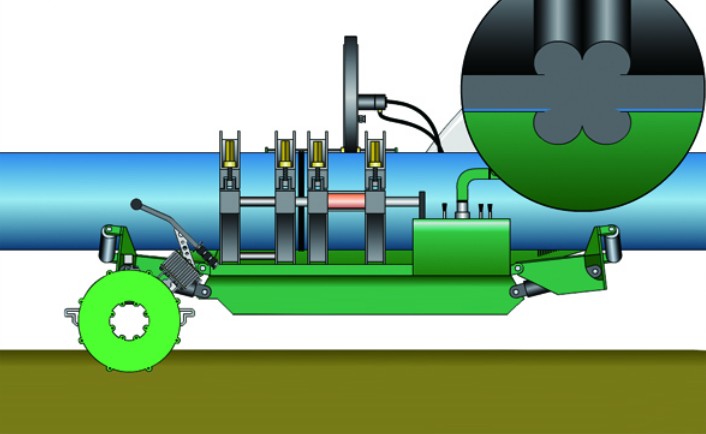

1. Butt Fusion Joining Method

Butt fusion joining method is a simple and fast PE pipe joining method. It is used more than diameter 63mm pipe and pipe joining, pipe and fittings joining.

2. Fitting Joining

PE pipe may be joined by injected fittings, butt fusion prefabricated fittings, steel-plastic joint and other mechanical fittings.

3. Flange Joining

Flange joining is used to join PE pipe and valve, or other material pipe and fittings.

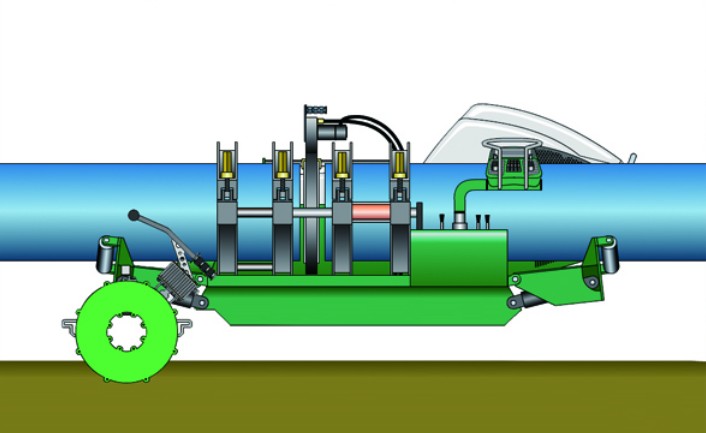

Butt Fusion Joining Procedure

|

||

| 1. Fix:Clamp the components in the machine. Check alignment of the ends and adjust as needed. | 2. Alignment:The pipe profiles must be rounded and aligned with each other to minimize mismatch (high-low) of the pipe walls. This can be accomplished by tightening clamping jaws until the outside diameters of the pipe ends match. The jaws must not be loosened or the pipe may slip during fusion. |

3.FACE:The pipe ends must be faced to establish clean, parallel mating surfaces, interfaces gap<0.3mm. Misplace less than fusion joint thickness. Re-clamp PE pipes must re-face pipe ends. |

|

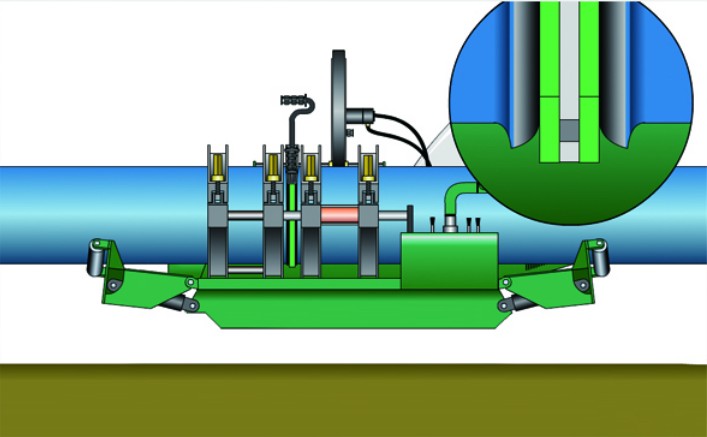

||

| 4. Measure drag force:Every time butt fusion must measure and record drag force. | 5. Heat, pressure, forming proper bead:Heating tools that simultaneously heat both pipe ends are used to accomplish this operation. To ensure that full and proper contact is made between the pipe ends and the heater, adjusts butt fusion pressure. Continue to hold the components in contact with each other, while a bead of molten polyethylene develops between the heater and the pipe ends. When the proper bead size is formed against the heater surfaces all around the pipe or fitting ends, stops pressure. | 6.Drop pressure:Drop pressure until drag force, insure the heater and the pipe ends close in contact each other, begin to heat. |

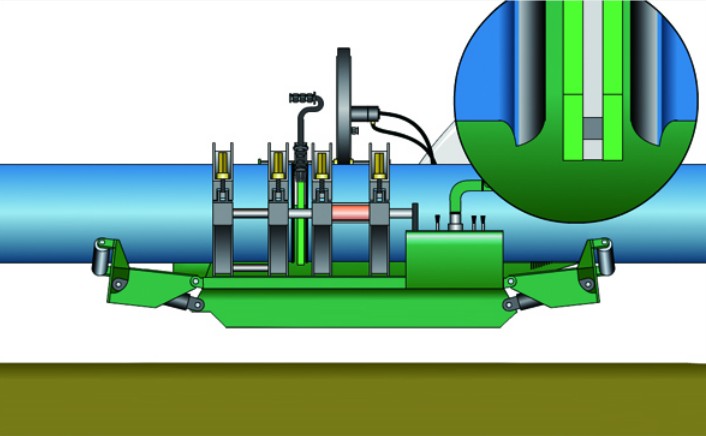

|

||

| 7. Take heater:After absorbed heating time, heater and the molten pipe ends are separated quickly, the heater tool is removed immediately. | 8. Raise pressure:Immediately bring the molten pipe ends together with sufficient fusion force to form a double rollback bead against the pipe wall. | 9. Hold Pressure and Cooling:Hold the joint immobile under fusion force until the joint has cooled adequately to develop strength. Allowing proper cooling times under fusion force prior to removal from the clamps of the machine is important in achieving joint integrity. |