// Specifications //

Modified poly vinyl chloride (PVC-M) pipe for water supply shall consist of polyvinyl chloride (PVC) resins together with the additives necessary for the manufacture and performance requirements of the Standard.

Baosu general manager and chief engineer are important makers of CJ/T272-2008 Modified poly vinyl chloride (PVC-M) pipes and fittings for water supply.Construction & Investment Baosu has advanced Germany Battenfeld PVC pipe extruders , PVC mixing system and forming socket equipment. Baosu™ PVC-M pipe is made by advanced production process and non-lead formula. Baosu™ PVC-M pipe is non-lead, and have been inspected and tested by Institute for Environmental Health and Related Product Safety Chinese Center for Disease Control and Prevention, Hebei Provincial Epidemic Prevention Station, Jiangsu Provincial Epidemic Prevention Station, which showed that the products respectively conform to the related standards.

Baosu™ PVC-M pipes are diameter 20 to 800mm, fittings are diameter 20 to 400mm injected fittings, diameter 400 to 800mm steel-plastic fittings. Baosu™ PVC-M pipes are widely used in transport and distribution, industrial, drainage and irrigation.

// Specifications //

| Nominal outside diameter, dn,mm | Nominal thickness, en,mm | |||||

| S25 | S20 | S16 | S12.5 | S10 | S8 | |

| SDR51 | SDR41 | SDR33 | SDR26 | SDR21 | SDR17 | |

| Nominal pressure, MPa | ||||||

| 0.63 | 0.8 | 1.0 | 1.25 | 1.6 | 2.0 | |

| 20 | 2.0 | 2.0 | ||||

| 25 | 2.0 | 2.0 | ||||

| 32 | 2.0 | 2.0 | ||||

| 40 | 2.0 | 2.4 | ||||

| 50 | 2.0 | 2.4 | 3.0 | |||

| 63 | 2.0 | 2.5 | 3.0 | 3.8 | ||

| 75 | 2.0 | 2.3 | 2.9 | 3.6 | 4.5 | |

| 90 | 2.0 | 2.2 | 2.8 | 3.5 | 4.3 | 5.4 |

| 110 | 2.2 | 2.7 | 3.4 | 4.2 | 5.3 | 6.6 |

| 125 | 2.5 | 3.1 | 3.9 | 4.8 | 6.0 | 7.4 |

| 140 | 2.8 | 3.5 | 4.3 | 5.4 | 6.7 | 8.3 |

| 160 | 3.2 | 4.0 | 4.9 | 6.2 | 7.7 | 9.5 |

| 180 | 3.6 | 4.4 | 5.5 | 6.9 | 8.6 | 10.7 |

| 200 | 3.9 | 4.9 | 6.2 | 7.7 | 9.6 | 11.9 |

| 225 | 4.4 | 5.5 | 6.9 | 8.6 | 10.8 | 13.4 |

| 250 | 4.9 | 6.2 | 7.7 | 9.6 | 11.9 | 14.8 |

| 280 | 5.5 | 6.9 | 8.6 | 10.7 | 13.4 | 16.6 |

| 315 | 6.2 | 7.7 | 9.7 | 12.1 | 15.0 | 18.7 |

| 355 | 7.0 | 8.7 | 10.9 | 13.6 | 16.9 | 21.1 |

| 400 | 7.9 | 9.8 | 12.3 | 15.3 | 19.1 | 23.7 |

| 450 | 8.8 | 11.0 | 13.8 | 17.2 | 21.5 | 26.7 |

| 500 | 9.8 | 12.3 | 15.3 | 19.1 | 23.9 | 29.7 |

| 560 | 11.0 | 13.7 | 17.2 | 21.4 | 26.7 | 33.2 |

| 630 | 12.3 | 15.4 | 19.3 | 24.1 | 30.0 | 37.4 |

| 710 | 13.9 | 17.4 | 21.8 | 27.2 | 33.9 | 42.1 |

| 800 | 15.7 | 19.6 | 24.5 | 30.6 | 38.1 | 47.4 |

// Characteristics //

PVC-M pipe keeps PVC-U pipe advantages, also has more other advantages.

1. Excellent resistant impact performance

PVC-M pipe enhances toughness compares with traditional PVC pipe, and excellent toughness may increase PVC-M pipe resistant impact performance and protect PVC-M pipe form destroy in installing and transporting.

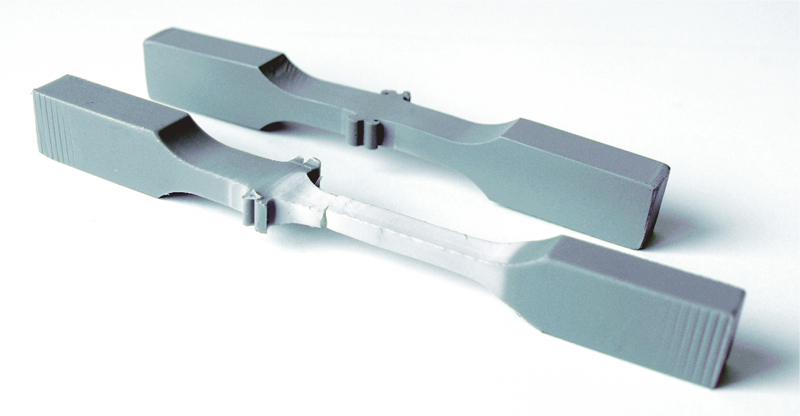

In 22℃,20m impact test showed PVC-M pipe toughness failure, PVC-U pipe brittle failure, see Fig.1 and Fig.2.

Fig.1 PVC-Ubrittle failure Fig.2 PVC-M toughness failure

2. Excellent resistant crack and point load performance

PVC-M pipe enhances resistant crack and point load performance, notched pipe test is a special test method of PVC-M pipe, PVC-U pipe doesn’t do this test.

Notched pipe test results show, notched PVC-M pipe long term strength is not affected, notched PVC-U pipe long term strength fall dramatically, reliability low.

Figure3 PVC-M Pipe hydraulic test long term performance curves(notched and unnotched)

3.Baosu second generation PVC-M pipe for butt fusion

Baosu first generation PVC-M pipe has enhanced toughness, but butt fusion strength is low, don’t meet trenchless technology.

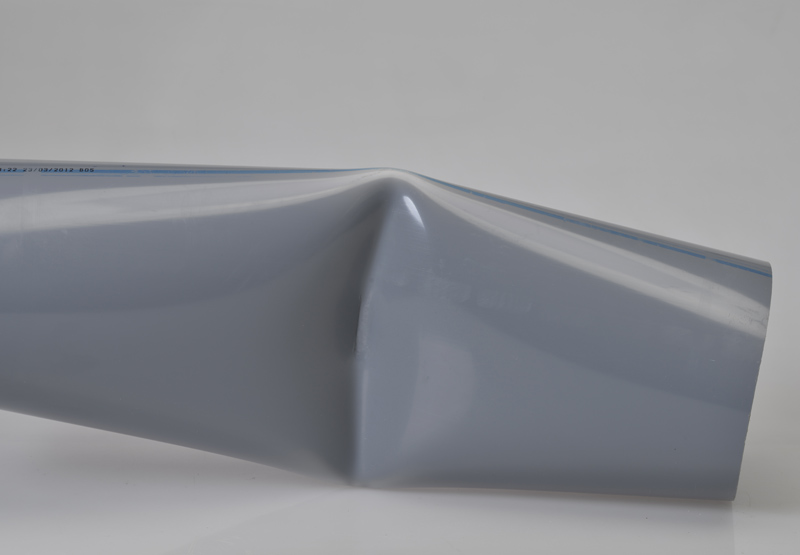

Baosu second generation PVC-M pipe may bend, make U type. It is used in trenchless and rehabilitated host pipe.

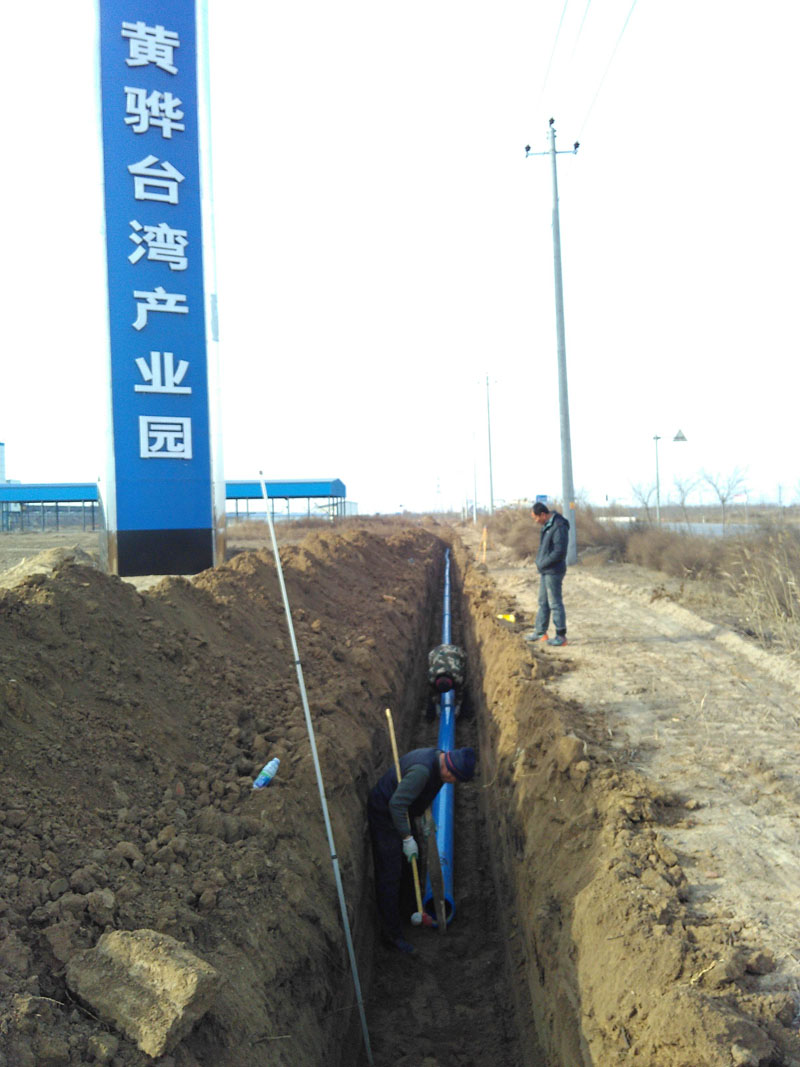

P1.Baosu second generation PVC-M pipe bend and folding.

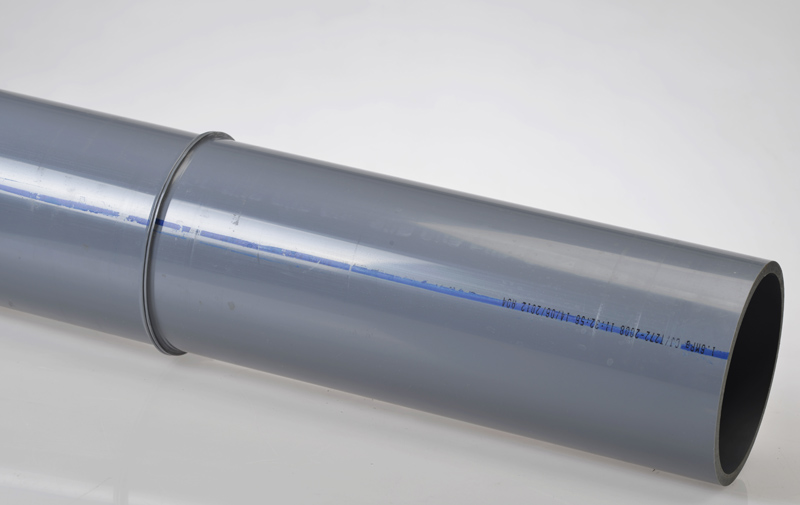

p2.Baosu second generation PVC-M pipe welding joint.

p3.Baosu second generation PVC-M pipe welding test sample.

// Performance and parameters //

CJ/T272-2008 Modified poly vinyl chloride (PVC-M) pipes and fittings for water supply requirements.

item |

technical index |

physical property

| |

Vicat softening temperature, ℃ |

≥80℃ |

Longitudinal reversion, % |

≤5% |

methylene chloride immersion test |

15℃±1℃,30min,surface no change |

| |

mechanical property | |

drop hammer impact test, 0℃ |

TIR≤5% |

drop hammer impact test, 22℃ dn ≥110mm |

no brittle failure |

hydrostatic test |

no break, no leakage |

notched pipe hydrostatic test |

no break, no leakage |

C-ring toughness test |

C-ring toughness test |

| |

Fitness for purpose of the system | |

item |

requirements |

joining seal test |

no break, no leakage |

deflection test |

no break, no leakage |

negative pressure test |

no break, no leakage |

note: only fitting for elastic seal ring joining method | |

| |

PVC-M pipe 20m drop hammer impact test | |

nominal outside diameter, mm

| hammer mass, kg | impact height, m |

110-140 | 10 | 20 |

160 | 15 | |

180-280 | 20 | |

315-400 | 25 | |

>400 | 30 |

Sample before impacted Sample after impacted

// hygiene performance //

Baosu PVC-M pipes and fittings meet GB/T17219-1998 Standard for Safety Evaluation of Equipment and Protective Materials in Drinking Water System and Standard for Hygienic Safety Evaluation of Equipment and Protective Materials in Drinking Water.

// hygiene performance //

Baosu™ PVC-M pipes are widely used in transport and distribution, industrial, drainage and irrigation.

// Installing //

PVC-M pipe construction and transport advance

1. transporting more safe

PVC-M pipe enhanced toughness can resist outside force impact in effect, reduce risk.

2. construction more safe

PVC-M pipes excellent resistant impact and toughness, reduce point load effect in construction.

3. more strong hydraulics performance

PVC-M pipe can be good for absorbing pressure wave, increase water supply efficiency, reduce operating cost.

4. rubber ring joint and solvent cement joint are more simple.

5. compared with PE pipeline, PVC-M pipeline has faster contruction, lower construction environment requirement, especially plenty of rain area,greater construction advantage.

T-S pipe jointing steps

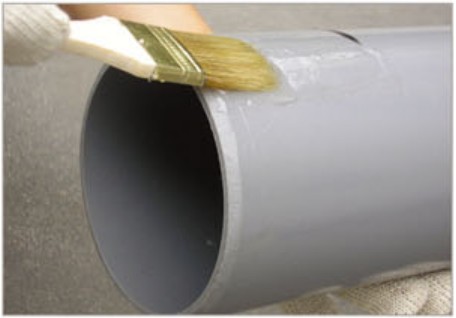

| 1.Cutting—pipe should meet requirements about dimensions, perpendicular cutting,bevel. | 2.Cleaning-outside spigot and inside socket dust and oils should be cleaned. | 3.Brushing- outside spigot and inside socket should be brushed quickly uniform cementing medium. |

| 4.Inserting-then quickly finding the center lines of the socket and spigot, inserting and spinning1/4 circle for cementing medium uniform spigot and socket seam. | 5.Keeping-after inserting until cementing medium solid, at least one minute, it should be removed surplus cementing medium in time. | 6.Completing-after jointing at least 10 minutes pipes should be not exerted loading. After 48hours pipeline can go on water test. |

R-R elastic rubber sealing ring jointing procedure

| 1. Socket slot inside surface and spigot outside surface should be cleaned by cotton cloth. | 2. Rubber sealing ring should be installed actually (big part inside, small part outside)and place the socket slot. | 3. Pipe spigot should be marked inserting depth line. |

| 4. Rubber sealing ring and pipe spigot uniform brush lubricant(prohibition oils). | 5.using tight thread device or manual calabash drags only a time to the mark line. | 6. Using plug ruler inspects rubber sealing ring installed among the circumference. |