// Introduction //  PVC-U irrigation pipes are made by polyvinyl chloride (PVC) resins and the additives necessary for the manufacture and performance requirements of the Standard.

BaosuTM PVC-U irrigation pipes meet GB/T 13664-2006 Unplasticized polyvinyl chloride (PVC-U) pipes for low-pressure conveyance in irrigation. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

// Specifications //

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1. Weight light, load and transport portable

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

// Application fields //

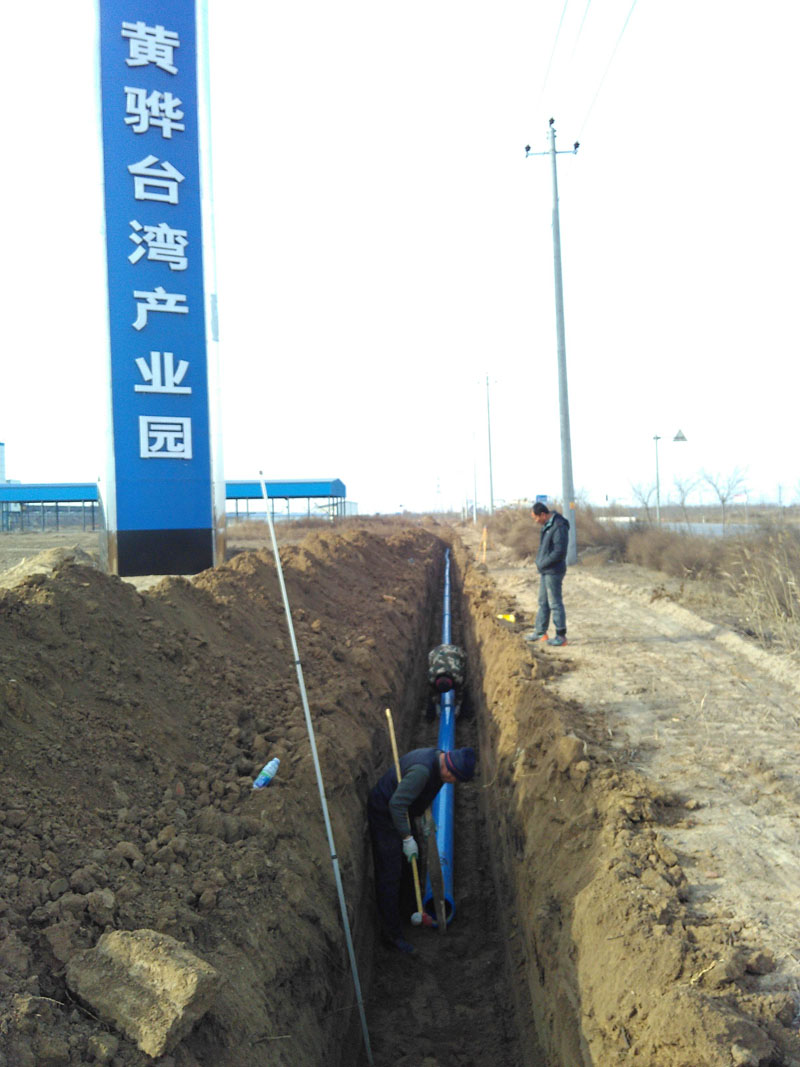

Baosu™ PVC-U irrigation pipes are widely applied in sprinkler irrigation, micro irrigation, low pressure conveyance. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

// Application fields //

Baosu™ PVC-U irrigation pipes installing methods: T-S jointing and R-R elastic rubber sealing ring jointing.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||