// Introduction //

RC-PO multi-layers compound pipe

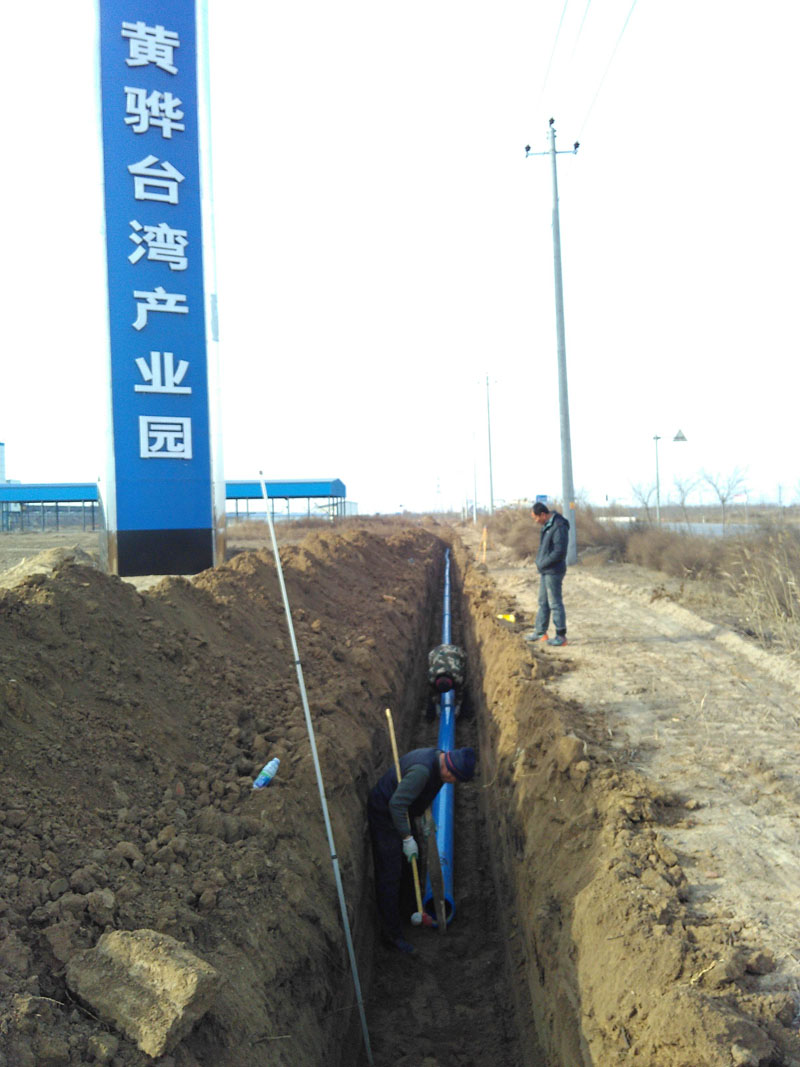

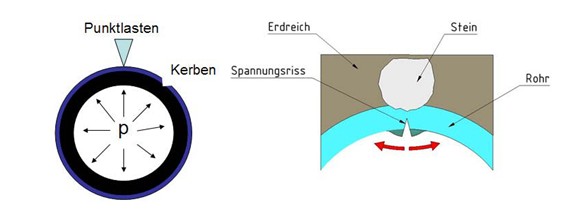

PE pipes easily are scratched in the traditional construction due to bad working conditions or non-standard construction, scratch may result in PE pipe stress concentration and crack propagation. If there are stones or other hard objects, and will have a point load of PE pipe damage, greatly influence the service life of PE pipe.

Our company cooperates with Total company, develop a new generation RC-PO cracking resistance of multilayer compoound pipe.

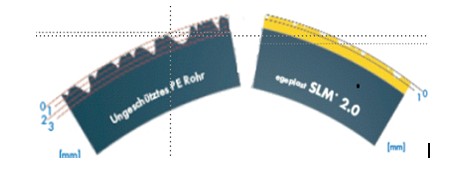

RC-PO multi-layers compound pipe outer layer made of super toughness blue PE raw materials, with a scratch performance superior resistance and point load ability of excellent resistance. There is safer and more service life.

// Specifications //

According to standard:

Triple layers super toughness polyethylene (PE100-RC) compound pipe

|

Nominal outside diameter, dn, mm |

Nominal wall thickness, (en, mm) , minimum inner layer thickness(In, mm) and outer layer thickness(Hn, mm) |

||||||||||||||

|

SDR26 |

SDR21 |

SDR17 |

SDR13.6 |

SDR11 |

|||||||||||

|

Nominal pressure, MPa |

|||||||||||||||

|

0.6 |

0.8 |

1.0 |

1.25 |

1.6 |

|||||||||||

|

en |

hn |

In |

en |

hn |

In |

en |

hn |

In |

en |

hn |

In |

en |

hn |

In |

|

|

90 |

|

|

|

4.3 |

0.7 |

2.5 |

5.4 |

0.9 |

2.5 |

6.7 |

1.0 |

2.5 |

8.2 |

1.3 |

2.5 |

|

110 |

4.2 |

0.7 |

2.5 |

5.3 |

0.8 |

2.5 |

6.6 |

1.0 |

2.5 |

8.1 |

1.3 |

2.5 |

10.0 |

1.5 |

2.5 |

|

125 |

4.8 |

0.8 |

2.5 |

6.0 |

0.9 |

2.5 |

7.4 |

1.1 |

2.5 |

9.2 |

1.4 |

2.5 |

11.4 |

1.7 |

2.5 |

|

140 |

5.4 |

0.9 |

2.5 |

6.7 |

1.0 |

2.5 |

8.3 |

1.3 |

2.5 |

10.3 |

1.6 |

2.5 |

12.7 |

1.9 |

2.5 |

|

160 |

6.2 |

1.0 |

2.5 |

7.7 |

1.2 |

2.5 |

9.5 |

1.5 |

2.5 |

11.8 |

1.8 |

2.5 |

14.6 |

2.2 |

2.5 |

|

180 |

6.9 |

1.1 |

2.5 |

8.6 |

1.3 |

2.5 |

10.7 |

1.6 |

2.5 |

13.3 |

2.0 |

2.5 |

16.4 |

2.5 |

2.5 |

|

200 |

7.7 |

1.2 |

2.5 |

9.6 |

1.5 |

2.5 |

11.9 |

1.8 |

2.5 |

14.7 |

2.2 |

2.5 |

18.2 |

2.8 |

2.8 |

|

225 |

8.6 |

1.3 |

2.5 |

10.8 |

1.6 |

2.5 |

13.4 |

2.0 |

2.5 |

16.6 |

2.5 |

2.5 |

20.5 |

3.1 |

3.1 |

|

250 |

9.6 |

1.5 |

2.5 |

11.9 |

1.8 |

2.5 |

14.8 |

2.3 |

2.5 |

18.4 |

2.8 |

2.8 |

22.7 |

3.4 |

3.4 |

|

280 |

10.7 |

1.6 |

2.5 |

13.4 |

2.0 |

2.5 |

16.6 |

2.5 |

2.5 |

20.6 |

3.1 |

3.1 |

25.4 |

3.8 |

3.8 |

|

315 |

12.1 |

1.9 |

2.5 |

15.0 |

2.3 |

2.5 |

18.7 |

2.8 |

2.8 |

23.2 |

3.5 |

3.5 |

28.6 |

4.3 |

4.3 |

|

355 |

13.6 |

2.1 |

2.5 |

16.9 |

2.6 |

2.6 |

21.1 |

3.2 |

3.2 |

26.1 |

4.0 |

4.0 |

32.2 |

4.9 |

4.9 |

|

400 |

15.3 |

2.3 |

2.5 |

19.1 |

2.9 |

2.9 |

23.7 |

3.6 |

3.6 |

29.4 |

4.4 |

4.4 |

36.2 |

5.5 |

5.5 |

|

450 |

17.2 |

2.6 |

2.6 |

21.5 |

3.3 |

3.3 |

26.7 |

4.0 |

4.0 |

33.1 |

5.0 |

5.0 |

40.9 |

6.2 |

6.2 |

|

500 |

19.1 |

2.9 |

2.9 |

23.9 |

3.6 |

3.6 |

29.7 |

4.5 |

4.5 |

36.8 |

5.6 |

5.6 |

45.4 |

6.9 |

6.9 |

|

560 |

21.4 |

3.3 |

3.3 |

26.7 |

4.0 |

4.0 |

33.2 |

5.0 |

5.0 |

41.2 |

6.2 |

6.2 |

50.8 |

7.7 |

7.7 |

|

630 |

24.1 |

3.7 |

3.7 |

30.0 |

4.5 |

4.5 |

37.4 |

5.6 |

5.6 |

46.3 |

7.0 |

7.0 |

57.2 |

8.6 |

8.6 |

|

710 |

27.2 |

4.1 |

4.1 |

33.9 |

5.1 |

5.1 |

42.1 |

6.4 |

6.4 |

52.2 |

7.9 |

7.9 |

64.5 |

9.7 |

9.7 |

|

800 |

30.6 |

4.6 |

4.6 |

38.1 |

5.8 |

5.8 |

47.4 |

7.2 |

7.2 |

58.8 |

8.9 |

8.9 |

72.6 |

10.9 |

10.9 |

|

900 |

34.4 |

5.2 |

5.2 |

42.9 |

6.5 |

6.5 |

53.3 |

8.0 |

8.0 |

66.2 |

10.0 |

10.0 |

81.7 |

12.3 |

12.3 |

|

1000 |

38.2 |

5.8 |

5.8 |

47.7 |

7.2 |

7.2 |

59.3 |

8.9 |

8.9 |

72.5 |

10.9 |

10.9 |

90.2 |

13.6 |

13.6 |

|

1200 |

45.9 |

6.9 |

6.9 |

57.2 |

8.6 |

8.6 |

67.9 |

10.2 |

10.2 |

88.2 |

13.3 |

13.3 |

|

|

|

// Characteristics //

RC-PO pipe advantages:

1. Super resistant external scratch

RC-PO pipe with a super slow crack growth resistance ability, can resist external scratch damage caused by a variety of reasons.

2.Excellent resistant point load

RC-PO pipes can effectively prevent the damage because of bad construction conditions and pipeline operation such as stone, metal and other hard material on the pipe caused by the point load.

3. Long term service life

RC-PO pipes have the normal service life of 100 years, during the construction process, even if the occasional external injury, because of the crack propagation speed only is common PE pipe one dozens.

// Performance and parameters //

RC-PO pipe inner layer and outer layer materials meet DIN-PAS1075 Pipes Made From Polyethylene For Alternative Installation Techniques - Dimensions, Technical Requirements And Testing. DIN-PAS1075 defines super toughness PE100material:

|

Test method |

Standard |

Requirements |

|

FNCT (80°C; 4 N/mm2 ; 2% Arkopal N-100) molding piece |

ISO 16770 |

> 8760 h |

|

Point load test dn110 SDR11 pipe (80°C; 4 N/mm2 ; 2% Arkopal N-100) |

PAS 1075, Hessel 3) |

> 8760 h |

|

Notched pipe test dn 110 SDR11 pipe (80°C; 9.2 bar; water) |

ISO 13479 |

> 8760 h |

|

Thermal stability test |

PAS 1075 |

> 20℃, 100 years |

Super toughness PE100 material better than common PE material

|

|

Super toughness PE100 material |

common PE100 |

ISO 4437 |

ISO 4427 |

GB/T 13663.1 |

|

Pressure grade |

MRS 10 |

MRS 10 |

MRS 10 |

MRS 10 |

MRS 10 |

|

200℃ hydraulic point |

> 100 h |

> 100 h |

> 100 h |

> 100 h |

> 100 h |

|

SCG |

|||||

|

Notched pipe test |

>8760 h |

1000 h |

> 500 h |

> 165 h |

- |

|

FNCT |

> 8760 h |

500 - 1000 h |

- |

- |

- |

|

RCP |

|||||

|

RCP S4 Pc at 0°C |

> 10 bar |

> 10 bar |

> 10 bar |

- |

- |

RC-PO pipe is not only suitable for the field of water and gas, especially suitable for the non - traditional construction technology, such as no sand laying, and trenchless,U type lining method, reducing lining method, pipe bursting, horizontal directional drilling method, plow etc.

// Installing //

RC-PO pipes has the same joining methods with common PE pipe, butt weld, electric fusion and mechanical fittings.

PC-PO pipes installing more cost and more save time. Pipeline backfill without the use of sand bed, reduce the installation cost of about 30-60%.

When pipeline renewal, trenchless and save over 50% time than traditional construction.