// Introduction //

Water supply PVC-U pipes and fittings are made by polyvinyl chloride (PVC) resins and the additives necessary for the manufacture and performance requirements of the Standard.

Baosu has advanced Germany Battenfeld PVC pipe extruders , PVC mixing system and forming socket equipment.

Baosu™ PVC-U pipe is made by advanced production process and non-lead formula. Baosu™ PVC-U pipe is non-lead, and have been inspected and tested by Institute for Environmental Health and Related Product Safety Chinese Center for Disease Control and Prevention, Hebei Provincial Epidemic Prevention Station, Jiangsu Provincial Epidemic Prevention Station, which showed that the products respectively conform to the related standards.

// Specifications //

Baosu manufactures PVC-U pipes and fittings following below standards:1.GB/T10002.1—2006

2.GB/T10002.2—2003

3.ISO4422.2:1996

4.DIN8062:1988

Table 1 GB/T 10002.1-2006 PVC-U Pipe Specifications

|

Nominal outside diameter, dn

|

|

||||||

|

0.63MPa |

0.8MPa |

1.0MPa |

1.25MPa |

1.6MPa |

2.0MPa |

2.5MPa |

|

|

thickness |

|||||||

|

20 |

|

|

|

|

|

2 |

2.3 |

|

25 |

|

|

|

|

2 |

2.3 |

2.8 |

|

32 |

|

|

|

2 |

2.4 |

2.9 |

3.6 |

|

40 |

|

|

2 |

2.4 |

3 |

3.7 |

4.5 |

|

50 |

|

2 |

2.4 |

3 |

3.7 |

4.6 |

5.6 |

|

63 |

2 |

2.5 |

3 |

3.8 |

4.7 |

5.8 |

7.1 |

|

75 |

2.3 |

2.9 |

3.6 |

4.5 |

5.6 |

6.9 |

8.4 |

|

90 |

2.8 |

3.5 |

4.3 |

5.4 |

6.7 |

8.2 |

10.1 |

|

110 |

2.7 |

3.4 |

4.2 |

5.3 |

6.6 |

8.1 |

10 |

|

125 |

3.1 |

3.9 |

4.8 |

6 |

7.4 |

9.2 |

11.4 |

|

140 |

3.5 |

4.3 |

5.4 |

6.7 |

8.3 |

10.3 |

12.7 |

|

160 |

4 |

4.9 |

6.2 |

7.7 |

9.5 |

11.8 |

14.6 |

|

180 |

4.4 |

5.5 |

6.9 |

8.6 |

10.7 |

13.3 |

16.4 |

|

200 |

4.9 |

6.2 |

7.7 |

9.6 |

11.9 |

14.7 |

18.2 |

|

225 |

5.5 |

6.9 |

8.6 |

10.8 |

13.4 |

16.6 |

|

|

250 |

6.2 |

7.7 |

9.6 |

11.9 |

14.8 |

18.4 |

|

|

280 |

6.9 |

8.6 |

10.7 |

13.4 |

16.6 |

20.6 |

|

|

315 |

7.7 |

9.7 |

12.1 |

15 |

18.7 |

23.2 |

|

|

355 |

8.7 |

10.9 |

13.6 |

16.9 |

21.1 |

26.1 |

|

|

400 |

9.8 |

12.3 |

15.3 |

19.1 |

23.7 |

29.4 |

|

|

450 |

11 |

13.8 |

17.2 |

21.5 |

26.7 |

33.1 |

|

|

500 |

12.3 |

15.3 |

19.1 |

23.9 |

29.7 |

36.8 |

|

|

560 |

13.7 |

17.2 |

21.4 |

26.7 |

|

|

|

|

630 |

15.4 |

19.3 |

24.1 |

30 |

|

|

|

|

710 |

17.4 |

21.8 |

27.2 |

|

|

|

|

|

800 |

19.6 |

24.5 |

30.6 |

|

|

|

|

|

900 |

22.0 |

27.6 |

|

|

|

|

|

|

1000 |

24.5 |

30.6 |

|

|

|

|

|

// Characteristics //

1. Weight light, load and transport portablePVC-U pipe proportion is only steel pipe and iron pipe 1/5, concrete pipe 1/3. Pipe weight is about the same specification and length ductile iron pipe 1/4, concrete pipe 1/10. Therefore, PVC-U pipe is load and transport portable and can reduce transport cost.1/2-1/3.

2. Resistant acid, no rusty, no corrode treatment.

3. No poisoning

PVC-U pipe is healthy and no poisoning. When operating no furring, no breed aquatic plants and other microbes, no second pollution for water.

4. Smaller flowing resistance

PVC-U pipe inside wall is smooth and smaller flowing resistance, manning coefficient is 0.008-0.009, CONVEY water is more than iron pipe 20%, and more than concrete pipe 40%.

5. Service life

Traditional pipe service life is 20-30years. PVC-U pipe service life is at least 50yearsat a set temperature and pressure..

6. High strength

In 23℃tensile strength is more than 45MPa.

7. Jointing convenient and installing simple

PVC-U pipe weight light and convenient, has some ductile. For installing ,comparable with other pipes, pipe system is more complex PVC-U pipe virtues is more prominent.

8. Repair easily

PVC-U pipe repairing cost is only ductile pipe or concrete pipe 30%.

// Performance and parameters //

PVC-U pipe for water supply performance|

item |

technical index |

|

Vicat softening temperature, ℃ |

≥80℃ |

|

Longitudinal reversion, % |

≤5% |

|

methylene chloride immersion test |

15℃,15min, surface no change |

|

drop hammer impact test, 0℃(TIR) |

≤5% |

|

20℃,42MPa,1h Hydrostatic test |

No damage, no leakage |

|

Integral sealing test(de>90,3.36×PN,20℃,1h) |

No damage, no leakage |

// Application fields //

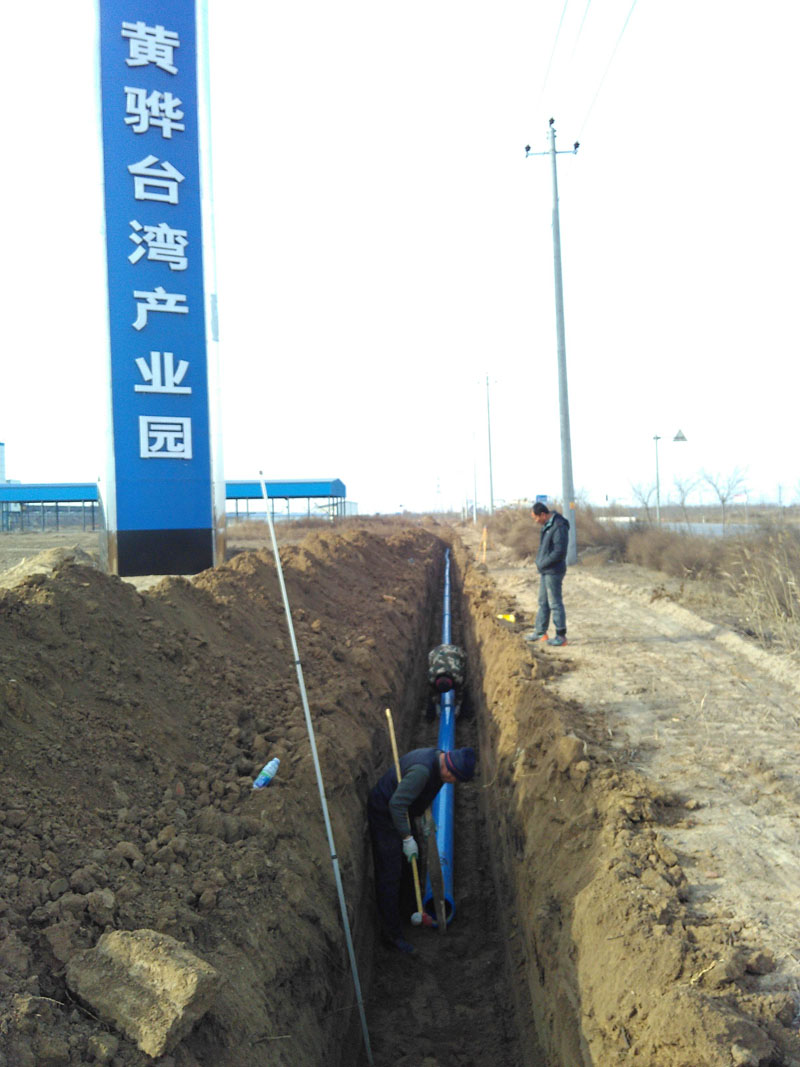

Baosu™ PVC-U pipes are widely applied the conveyance of water up to and including 45 °C, following applications: city-and-town source engineering, urban and suburb municipal water supply net, indoor water supply,well, irrigation, industrial, planting and mine.

// Installing //

R-R elastic rubber sealing ring jointing procedure1. Socket slot inside surface and spigot outside surface should be cleaned by cotton cloth.

2. Rubber sealing ring should be installed actually (big part inside, small part outside)and place the socket slot.

3. Pipe spigot should be marked inserting depth line.

4. Rubber sealing ring and pipe spigot uniform brush lubricant(prohibition oils).

5.using tight thread device or manual calabash drags only a time to the mark line.

6. Using plug ruler inspects rubber sealing ring installed among the circumference.

Installation diagram:

T-S jointing steps

1.Cutting—pipe should meet requirements about dimensions, perpendicular cutting,bevel.

2.Cleaning-outside spigot and inside socket dust and oils should be cleaned.

3.Brushing- outside spigot and inside socket should be brushed quickly uniform cementing medium.

4.Inserting-then quickly finding the center lines of the socket and spigot, inserting and spinning1/4 circle for cementing medium uniform spigot and socket seam.

5.Keeping-after inserting until cementing medium solid, at least one minute, it should be removed surplus cementing medium in time.

6.Completing-after jointing at least 10 minutes pipes should be not exerted loading. After 48hours pipeline can go on water test.

Installation diagram: