// Introduction //

For meeting liner pipe market demand, our company develops a new type plastic pipe, resistant high temperature polyolefin alloy pipe (HT-PO) for industrial applications. The new type pipe has gained three national patents, with good foreground in many applications.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

// Characteristics //

1.Work temperature wide (-70℃—110℃). 2.Excellent chemistry stability and resistant erode. 3.Resistant abrasion, in the same condition, resistant abrasion performance is steel pipe four times. 4.Easy join, construction time short, no necessary maintain, after restore and working. 5.Restore cost low, about new pipe line 60%. 6.Increase resistant pressure strength of pipe line 20-40%. 7.Liner layer smooth, no deposit, no grow bacteria, reduce friction. 8.Suit for DN100-DN3000 many kinds material pipes. 9.No necessary excavate complete pipeline, may install 1000-1500m a time. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

// Performance and parameters //

HT-PO pipes according to standard: Q/JTBS001-2011 Resistant high temperature lining polyolefin alloy pipe (HT-PO)

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

// Application fields //

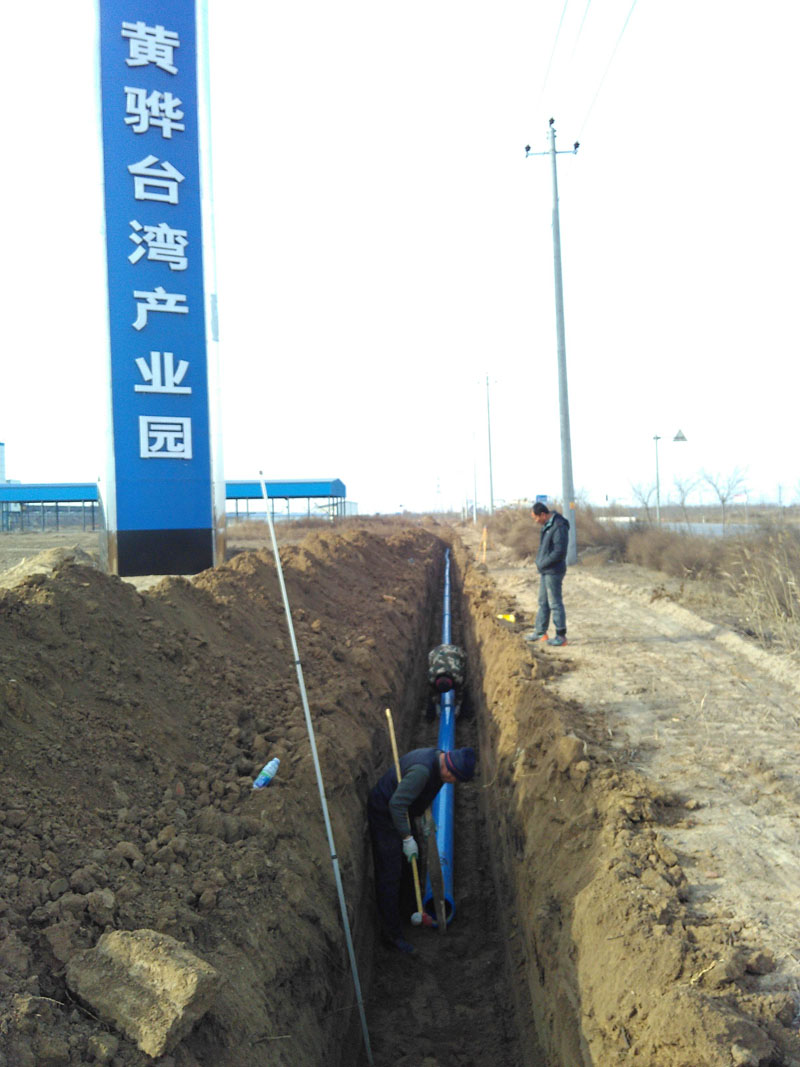

Transport oil, gas, oil and gas, and sullage pipes in oil field, many years has eroded and holed problems. If host pipe use liner pipe resistant erode and restore procedure, it can reduce investment, construction time short, resistant erode good, long lifetime. HT-PO pipe is the choice for high temperature transport.

Natural gas pipes work pressure higher coal gas pipes, when using exist cast iron pipes (socket and spigot joint) transport natural gas, liner HT-PO pipe may improve pipeline work pressure grade, prevent leakage, meet transport natural gas pressure requirement.

Liner pipe, increase pipeline resistant abrasion performance, no deposit, high transport efficiency, save production cost, extend lifetime.

No necessary excavate complete pipeline, liner HT-PO pipe in host pipe, solve second polluting problem for water supply, construction cost only about new pipe line 60%.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||