// Introduction //

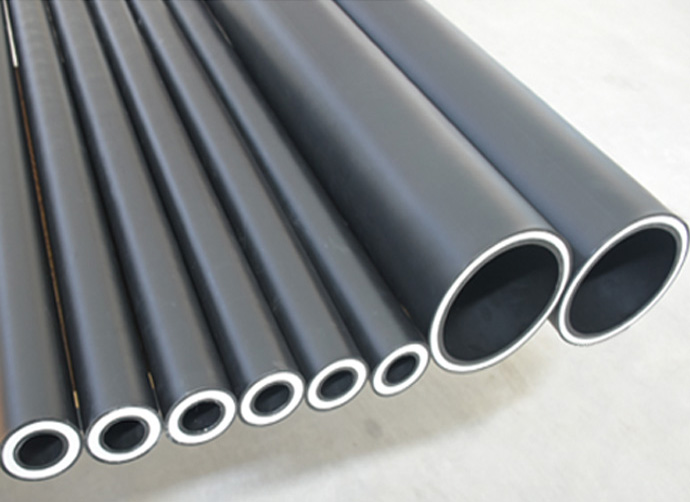

With 30 years of R&D experience in plastic pipeline and profoundly research in the oil field market, Hebei Construction & Investment Baosu Pipe Industry Co., Ltd. has successfully developed the latest generation of pipe, the Continuous fiber tape reinforced integral fusion type—Reinforced Thermoplastic coiled Pipes (CFTF-RTP) which has the characteristics of temperature resistance, pressure resistance, corrosion resistance, liner collapse resistance and oil swelling resistance, and directly replaces the traditional pipe for oil and gas transportation, reduce energy consumption. Safer operation, longer service life and more assured use.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

// Specifications //

GB/T 38725.2-2020 Spoolable reinforced plastic pipe—Part 2: Fiber reinforced thermoplastic coiled pipe SY/T 6794-2018 Spoolable reinforced plastic line pipe SY/T 6769.5-2016 Specifications for the design, construction and acceptance of non- metallic pipelines—Part 5 : Fiber reinforced thermoplastics coiled composite pipes SY/T 6770.5-2016 Quality acceptance code for non-metallic pipelines—Part 5 : Fiber reinforced thermoplastics coiled composite pipes.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

// Characteristics //

1. Performance advantages brought by the reinforced materials 1) High strength: 2) Insensitive to temperature and time, more suitable for conveying high temperature medium (≤75℃) 3) More resistant to corrosion by oil and gas medium 2.Performance advantages brought by the overall welding structure Because the CFTF-RTP pipe has an isomorphous structure between layers, the three layers completely form a whole, which effectively solves the defects of physical interface bonding. So it has more excellent performance: 1)Strong resistance to slow crack growth, higher pipeline safety. 2)If the pipe needs to be broken during construction, the overall performance will not be affected, and the connection safety will be higher. 3)Good rigidity and safer operation. 4)Good linear expansion resistance and stronger adaptability to operating environment. 5)The uniform prepreg and integral bonding structure of the glass fiber make the reinforced material be effectively protected and the pipeline life is longer. 6)Better gas permeability resistance, more suitable for conveying oil and gas mixed medium. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

// Performance and parameters //

According to GB/T 38725.2-2020, glass fiber reinforce polyethylene coiled pipe is X type.And the glass fiber reinforce polyethylene of raised temperature resistance coiled pipe is XI type. The corresponding highest operation temperature is 60℃ and 70℃。 The physical and mechanical characteristics are shown in the following table:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

// Installing //

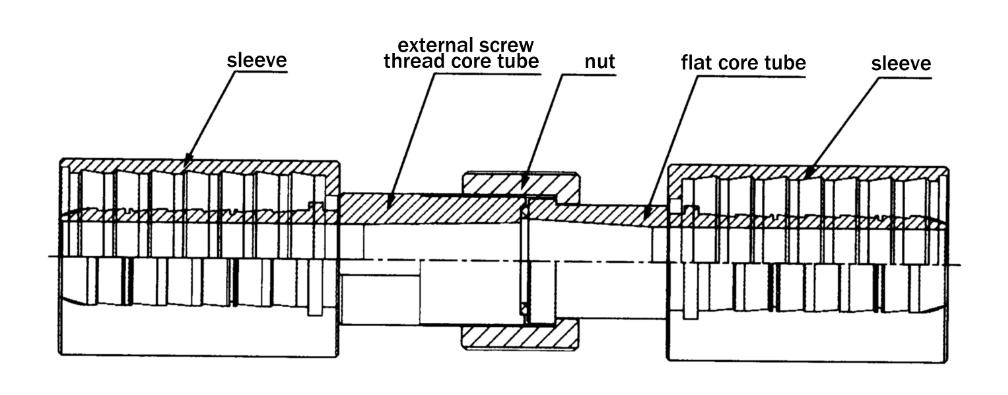

1.Compared with the traditional connection mode, the internal expansion and external contraction connection mode of CFTF-RTP pipe has significant advantages. 1) The strength and integrity of the glass fiber reinforced layer are not affected by the mechanical deformation of the metal joint, which improves the safety of the joint; 2) With the uniform circumferential compression at the joints ,the pipe have better connection; 3) The integral structure improves the ability of the joint to resist axial pull load. 4) Compared with the traditional , the inner diameter loss of the joint is reduced and the fluid conveying capacity is basically unaffected. 2. The special equipment provided by our company is required for the connection of pipes and joints. 3. Pressure test. It is divided into tightness test and strength test. The tightness test pressure is the design pressure, and the strength test pressure is 1.25 times of the design pressure.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

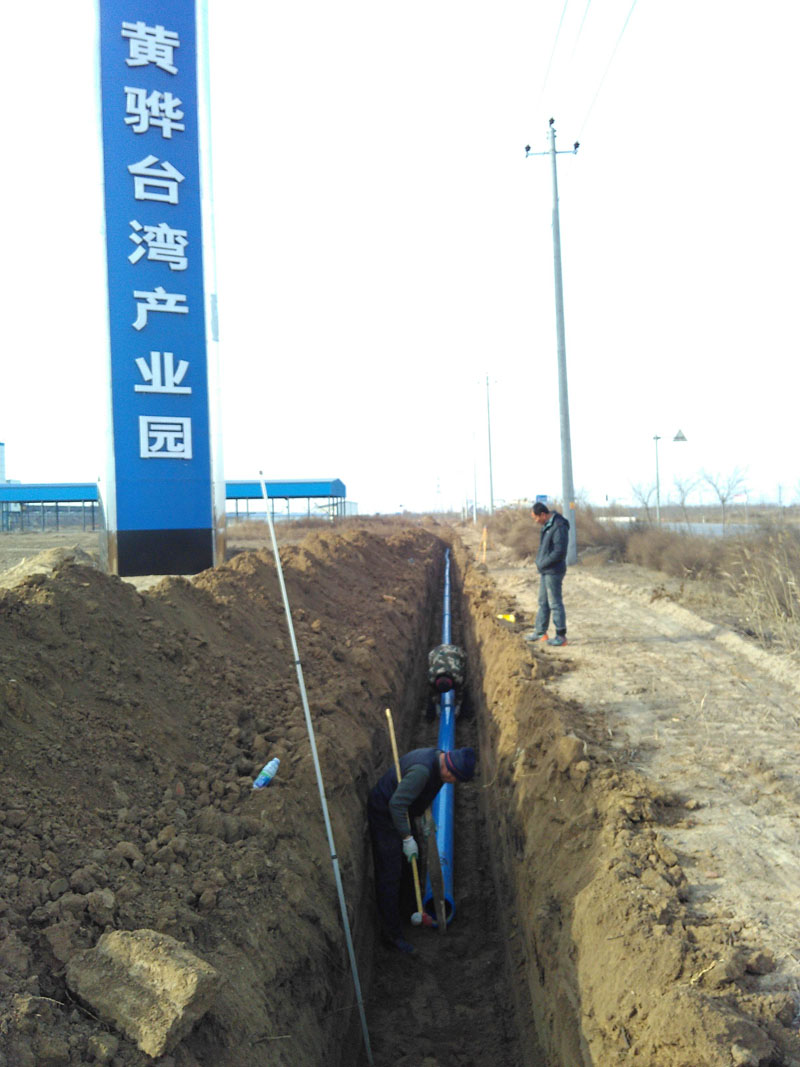

// Applications //

Alcohol injection Waste Water reinjection Water injection Crude oil gathering and transportation Natural gas gathering and transportation Shale gas and coalbed methane |